The financial viability of decentralized biochar production systems is gaining attention as global agriculture and energy sectors pursue carbon-smart technologies. Small-scale production units, designed for local deployment, enable farmers, cooperatives, and rural enterprises to convert agricultural residues into carbon-rich materials. Evaluating the economic performance of these systems requires analyzing equipment cost, feedstock utilization, energy recovery, and market potential of the resulting biochar.

Equipment Investment and Capital Structure

Initial capital outlay is the principal determinant of project feasibility. A small charcoal making machine, engineered for low-volume continuous operation, typically requires modest investment compared to industrial systems. Its compact structure allows installation in confined rural facilities, reducing logistical expenses and infrastructure requirements. The simplicity of design, coupled with automated temperature control, minimizes labor dependency and maintenance overhead.

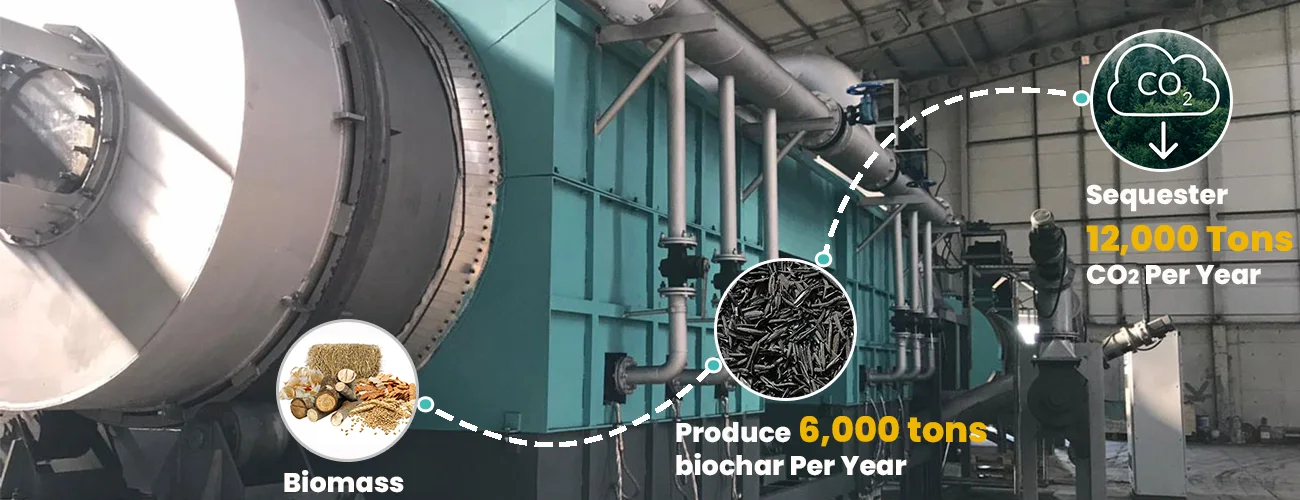

The availability of a biochar kiln for sale in regional markets has expanded options for small producers seeking cost-effective solutions. These units, fabricated from heat-resistant steel and equipped with energy recovery modules, transform organic residues into high-quality biochar with minimal emissions. Financing mechanisms—such as microcredit schemes and agricultural subsidies—further lower entry barriers for rural adopters, improving overall investment attractiveness.

Feedstock Economics and Resource Efficiency

Feedstock composition and procurement costs directly influence production margins. Agricultural residues such as husks, shells, and pruned branches are typically available at low or zero cost, providing a favorable input base for decentralized units. The biomass carbonization machine maximizes conversion efficiency by controlling pyrolytic temperature and gas recirculation, ensuring high carbon yield per ton of raw material.

Self-sustaining combustion systems that reuse generated syngas for heating significantly reduce energy expenditure. This thermodynamic efficiency allows small operators to maintain profitability even under variable feedstock moisture or calorific conditions. Integration with waste management programs also generates ancillary income through tipping fees or carbon credit schemes, further enhancing the financial outlook.

Market Potential and Product Valorization

The commercial success of small-scale biochar operations depends on the end-use market. Biochar is widely utilized as a soil amendment, water filter medium, and additive in livestock feed or construction composites. With growing interest in regenerative agriculture and carbon sequestration, demand for high-quality biochar continues to rise.

Producers utilizing a biochar maker for sale can diversify income by offering customized carbon materials for local farms, nurseries, or horticultural enterprises. Additional revenue can be derived from co-products such as wood vinegar and combustible gases, both of which have established industrial and agricultural applications. Establishing cooperative networks among small producers enhances market penetration and ensures supply consistency.

Profitability Outlook and Payback Analysis

Economic assessments indicate that well-managed units can achieve payback within two to four years, contingent upon feedstock availability and market pricing. The decentralized configuration reduces transportation costs and fosters energy independence in rural economies. Modular biochar kiln for sale scalability enables operators to incrementally expand capacity without incurring disproportionate capital costs.

As global carbon markets mature and sustainability metrics gain prominence, small-scale biochar production units are positioned as viable micro-enterprises. Through efficient resource use, low operational expenditure, and multi-product revenue streams, they embody a practical convergence of environmental stewardship and economic resilience.